On the factory floor

Repairing clothes was second nature to our grandparents. They bought well and repaired well. Now we are slowly starting to see the reemergence of appreciation for items that are well made and Grenson is one brand that has been there since the start.

Let’s play a game of word association. ‘Cashmere’, Scotland. ‘Tailoring’… that’s easy, Savile Row. ‘Cotton’… Egypt and California. And for ‘footwear’? You would be right in thinking about the area of Northamptonshire. Near enough all of our English footwear brands are based in the towns in and around Northampton. They’ve just got a nac for a goodyear welt and fully understand the importance of a good derby, loafer and the rest of them.

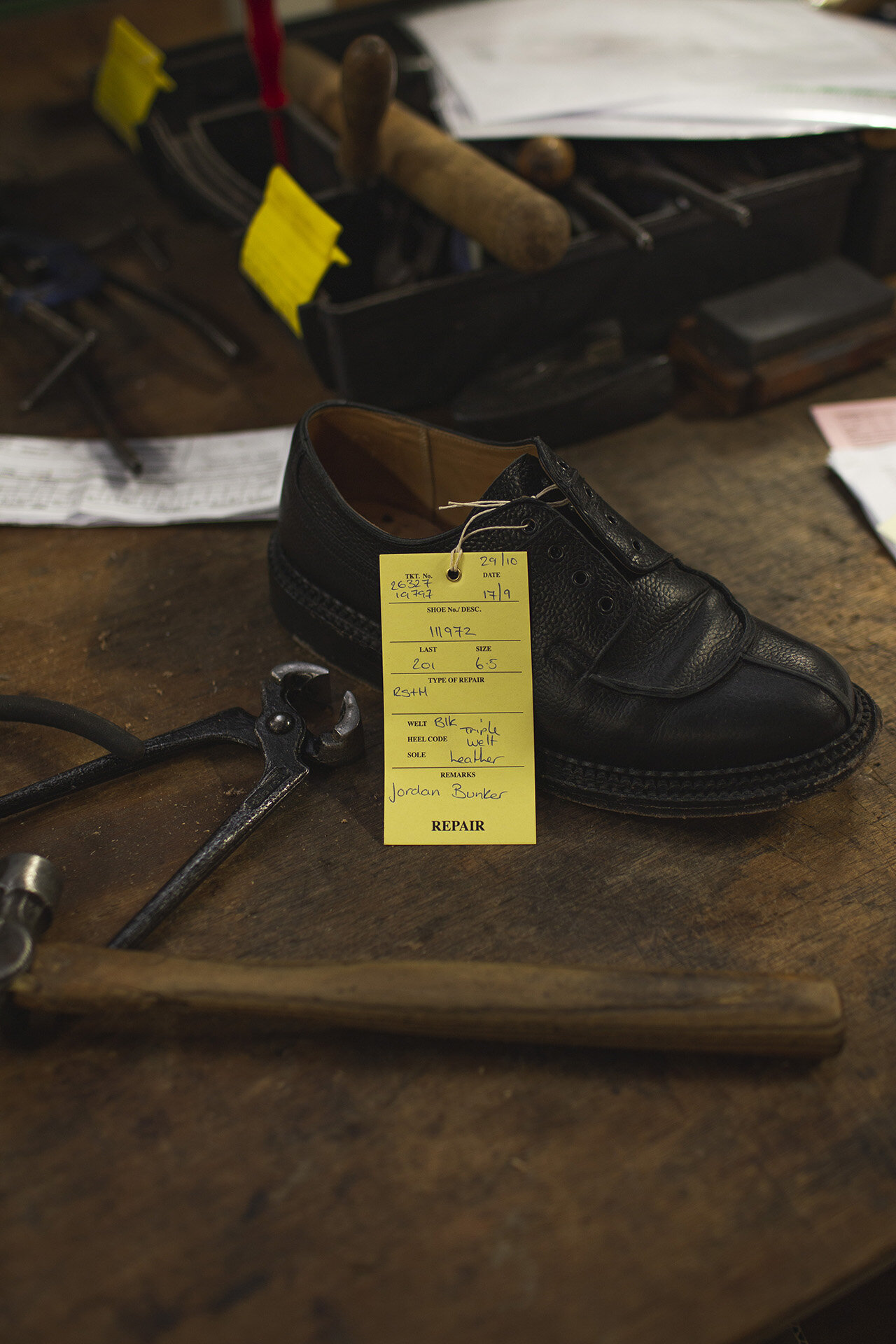

Being a short journey away meant that when Grenson shone a light on their shoe repair service, I was quick to drop them a message that went something along the lines of: “my pair of percy triple-welts have seen better days, would it be possible to a) spruce them up using the service and b) tag along in the factory while they do it?” Now this was spoke about back in October and it is only now where I’ve been able to share this, but what I find enjoyable about this is that this is not a blog post about a new shoe and the marketing push has been and gone, this is about the beauty of repairing something old and something that we should continue to talk about. Repair over replace.

So there I was, on the factory floor with a pair of shoes I had on earlier in the week, ready to be given their MOT, Grenson edition. Looking inside a factory is always a privilege. I consider it a big perk and to meet the people that make the shoes I wear… well that’s special.

The first thing that happens is the worn away heel is removed, the outersole is prised away and the cork filling scraped away. Each repair has its own steps, but the approach is similar on each occasion. It’s a case of taking off all the worn and damaged parts to leave the core of the original shoe to work with on the factory floor.

All of Grenson’s shoes are Goodyear Welted, a shoemaking technique that allows for shoes to be repaired. The beauty of keeping an upper and insole is that it’s like replacing wheels on a car, with the body’s individualities still in-tact, which in shoe terms means you won’t have to break them in again.

With the shoe wrapped up and with the original last placed inside to avoid any damage being done to the upper while it goes around, the team get to work on the rest of it. There are so many steps of various sizes that help bring a shoe back to life, some of them being: threading through the new stitching, applying fresh cork resin for extra comfort, constructing the new triple welt, smoothing out the wooden heel and outersole, painting the replaced shoe parts and applying the triple welt markings, before being left to dry ahead of the final buff. All of which would deceive you into thinking that you’re receiving a new pair of shoes up until you slip them back on.

What I enjoyed seeing is that there were no shoes going around by themselves via a conveyer belt. They went from person to person, all adding their expertise and craftsmanship to the shoe before finally making it back to the box they arrived in. In between taking photos I was able to have conversations with employees that had been in the job for thirty plus years, talk to the man who designed the triple-welt and then chat to those who were new to the factory floor and learn why they chose to work here. All of which had amassed an incredible amount of knowledge when it came to footwear and something I’m only beginning to grasp.

My time on the factory floor came to an end as I saw my shoes wheeled off to dry. Since my visit, talks of a return trip are on the cards but this time I’ll probably be wearing my percys over seeing them replaced again. But rest assure, when it’s time for it they’ll be back in some very capable hands.jbicon

Could 2023 be the ultimate year of sustainability for fashion? Probably not, but there are some positive things happening if you look for them.